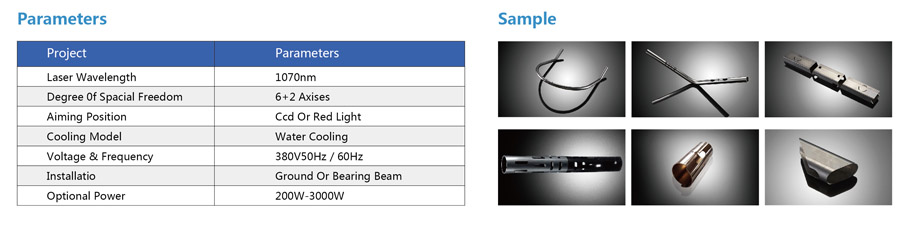

Introduction & Application

The three-dimensional fiber laser cutting robot is an advanced laser cutting equipment with flexible

cutting of metal plates with different thicknesses from different angles and directions by special fiber laser

cutting head, high precision capacitance tracking system, fiber laser and industrial robot system. Based

on the flexible and fast motion performance of industrial robots, according to the size of the work piece cut

by users. The robot is directly or reversely loaded and programmed by teaching or off-line programming for

different products and trajectories. The irregular work piece is cut by a fiber laser cutting head and the laser

is transmitted to the cutting head. The cutting head is equipped with special optical fiber servo device and

optical transmission device, and then focusing system can be used for multi-directions cutting of

a variety of three-dimensional metal sheets.

According to the thickness of metal sheet, the power of the selected fiber laser is different. Different

cooling systems are equipped for different power lasersto ensure the normal operation. At the same time,

according to the working radius of the manipulator and the size of the work piece processed by the customer,

the appropriate length of the operating optical fiber transmission laser should be selected to suit the cutting

requirements of the customer.

It is widely used in automobile manufacturing, construction machinery, aerospace,Three-dimensional sheet

metal processing and other industries.Successfully replacing blanking die, trimming die, etc., greatly shorten the

product development period and save high investment in die.

Equipment advantage

? The perfect combination of advanced optical fiber laser technology and digital control technology ,

which represents the most advanced laser cutting level.

? The mechanical structure adopts imported manipulator and six-axis linkage. The laser beam guiding

device is fully integrated into the manipulator arm.Combining the advantages of stable laser and moving

robot arm, the processing of arbitrary and specific curves in three-dimensional space can be realized.It

is easy to operate and high intelligence, which greatly reduces the period and ensures the high running

speed, high precision and high speed of the equipment. high reliability.

? Equipped with professional motion control software to ensure cutting quality, ensure stable operation

of equipment, make cutting more convenient and operation more convenient.

? Imported precision laser cutting head, sensitive response, accurate cutting, and effective cooperation

with the manipulator, avoid cutting head and processing metal sheet collision, ensure the cutting focus

position, ensure the cutting quality stability.

? The combination of industrial robot and optical fiber laser is used to process, so that the processing can

be completed at one time, the incision is neat that need not process. The treatment greatly shortens the

processing time, reduces the labor cost and die cost, and also improves the product grade.

? Industrial robots greatly reduce the cost of the system, reduce the cost of power consumption system,

system operation and maintenance costs. The area of equipment is reduced.

HyTube Series Ⅰ Automatic Prof…

Technology Advantage? Using the bus numerical control system based on Windows operating s…

HyPulsar Cheetah Series Laser C…

Introduction & Application HyPulsar cheetah series laser cutting system integration …

HySonics Eagle Series Laser Cut…

Introduction & Application HySonics series is high-speed and high-power fiber laser c…

HySonics-R Series Tube & S…

Technology Advantage◆ Independently develops the integrated machine of sheet and tube. It…

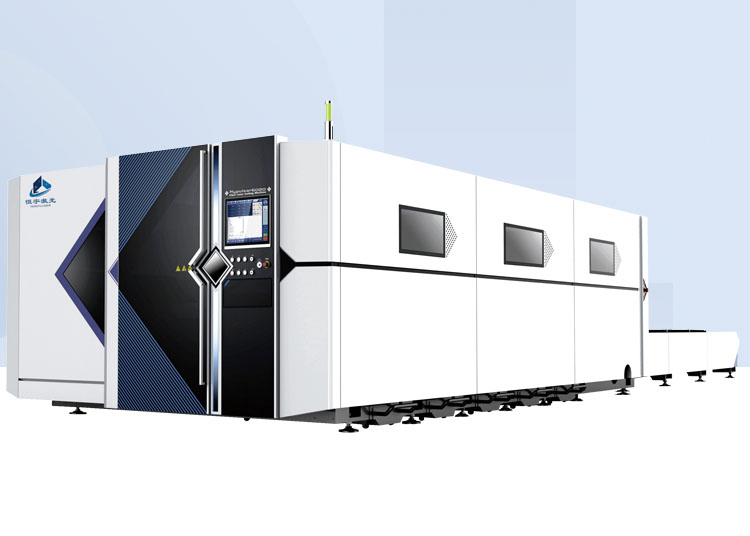

3D-metal laser cutting machine

Introduction & Application The three-dimensional fiber laser cutting robot is an adv…